Description

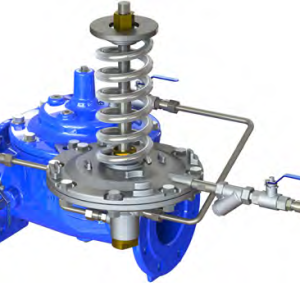

KARX – Combination Kinetic Air Release Valve

Features:

– Advanced design with a simple mechanism, strong float to prevent cracking during sudden water hammer & quick closure.

– Aerokinetic mechanism to resist blow shut under higher air velocity even up to a sonic air velocity.

– For the potential water hammer location or transmission pipeline, we should use an anti-shock combination air valve to prevent damage or impact of severe water hammer.

– An anti-shock device is installed on top of the bonnet, It will slow down the exhausting air flow out during filling to prevent hammer impact, whenever a vacuum happens, the device will drop down and let Large air into the pipeline.

– There are no arms or levers to prevent vibrating, bending, or direct closure of the float.

– Smooth cage outside the float, keep the float moving in the specified guide rail.

– Bottom rubber buffer for collision prevention, and drain easily with proper holes around the cage during vacuum

– Outside screens will be an option for safety and to prevent insects or birds.

– Fully fusion epoxy coated inside and outside valve body for long-term services.

– Manufacturing standard meets or exceeds BS EN 1074-4, AWWA C512

– Flange drilling and dimension meets BS EN 1092 BS EN 558 and ANSI flange.

General Application:

For water systems, fire fighting, irrigation systems

Technical Data:

Size Range: DN50~DN300mm

Pressure Ratings: 1.0Mpa; 1.6Mpa;2.5Mpa (Thread) 1.0Mpa,1.6Mp,2.5 Mpa(Flange)

Working Temperature:-10C- 80C

Suitable Media: Clean Water

Please consult the factory for PN40 and anti-shock device whenever there is a water hammer issue