Description

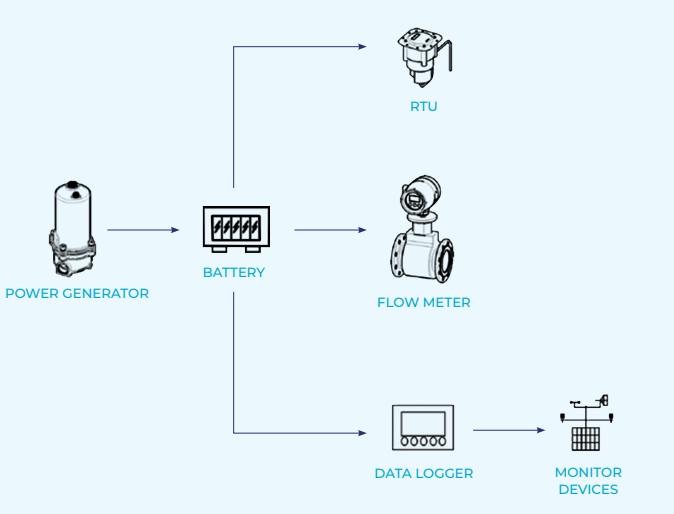

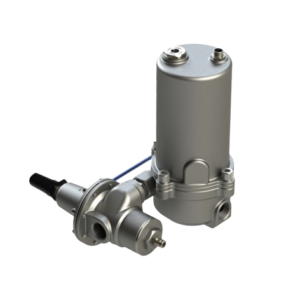

MHPG – Hydraulic Power Generator

Features:

1. Material of Construction:

– Body: Stainless Steel (S/S) 304

– Rotor Shaft: Stainless Steel (S/S) 304

2. Power Generation:

– The Hydraulic Power Generator utilizes the hydraulic fluid’s flow rate and differential pressure (delta P) to generate power.

– The movement of the fluid, such as water, pushes a series of blades mounted on a rotor shaft.

– The force of the fluid on the blades rotates the rotor shaft of the generator, converting the mechanical (kinetic) energy into electrical energy.

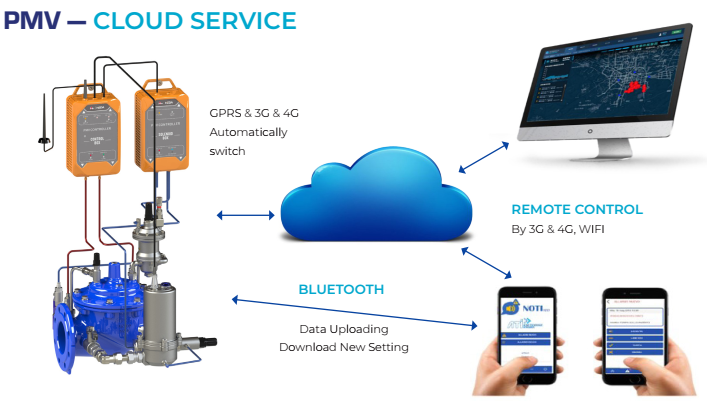

– This electrical energy can be utilized to power various devices and systems.

– Adjustable output voltage 0.5v – 30v

3. Ceramic Bearings:

– Equipped with ceramic bearings that provide exceptional durability and a long operational life span.

– Ceramic bearings offer high strength, low friction, and superior resistance to wear and corrosion.

– Including ceramic bearings ensures trouble-free performance and reduces the need for frequent maintenance or replacements.

4. Turbine Speed Control:

– The turbine speed is controlled using a differential control pilot.

– The differential control pilot adjusts the flow rate and pressure differentials within the hydraulic system, regulating the turbine speed effectively and thereby controlling the current

– This control mechanism enables precise control over the power generation process, optimizing efficiency and performance.

Power Output and Differential Pressure

• 0.1 bar: 4-6 mA

• 0.2 bar: 10-12 mA

• 0.3 bar: 30-40 mA

• 0.4 bar: 60-70 mA

• 0.5 bar: 85-95 mA

• 0.6 bar: 110-140 mA

• 0.7 bar: 150-160 mA

• 0.8 bar: 170-180 mA

• 0.9 bar: 180-190 mA

• 1.0 bar: 190-200 mA

• 1.2 bar: 190-210 mA

• 1.3 bar: 190-210 mA