Description

Wafer Unidirectional Knife Gate Valve

Technical Data

Size: DN 50 to DN 600 (larger diameters on request)

Working pressure:

DN 50 to DN250 10 Bar NPS 2-10 150 psi

DN 300 to DN450 7 Bar NPS 12-18 90 psi

DN 500 to DN600 4 Bar NPS 20-24 60 psi

DN 700 to DN1200 2 Bar NPS 28-52 30 psi

Standard flange connection:

EN1092 GB/T 9113

ASME B16.5 AS 2129/4087

JIS B2220 Others on request

Application:

Pulp and Paper/ Mining /Waste Water Treatment/ Food and Beverage/Chemical Plants/ Power Plants/ Steel Industry/Etc.

Note: Hand wheel nut is available for valve without stem protector. Non-stainless parts are epoxy coated.

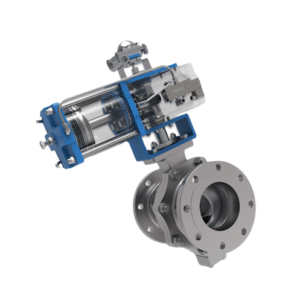

BODY:

• Cast-in guide claws at the port bottom for gate fixture, instead of a groove, eliminate

potential valve shutoff clogging while providing a tighter seal.

• Integral body design ensures easy assembly and 0 shell leakage.

• Full port design minimizes pressure drop and maximizes flow capacity.

• PTFE resilient point against gate eliminate metal-metal contact between gate and body.

GATE:

• Beveled knife edge provides strong cutting stress and tight sealing.

• Gate thickness can be increased to meet higher pressure.

• Gate surface is well polished on both sides for a tight seal and less jamming.

• Gate is hard chrome coated for the metal sealing valve.

SEAT:

• Side-entry seat is replaceable, reducing the cost of maintenance.

• Preloaded seat is adjustable to meet different sealing classes and compensate for sea wear.

• L-shape seat retainer locks the seat into the valve body and covers the seat side to prevent direct flow flushing.

Other:

• Stem cover is available to ensure long service life for the stem.

• Two thrust bearings minimize torque for operation.

• Grease nipple is available to ease bearing lubrication.